Our Services

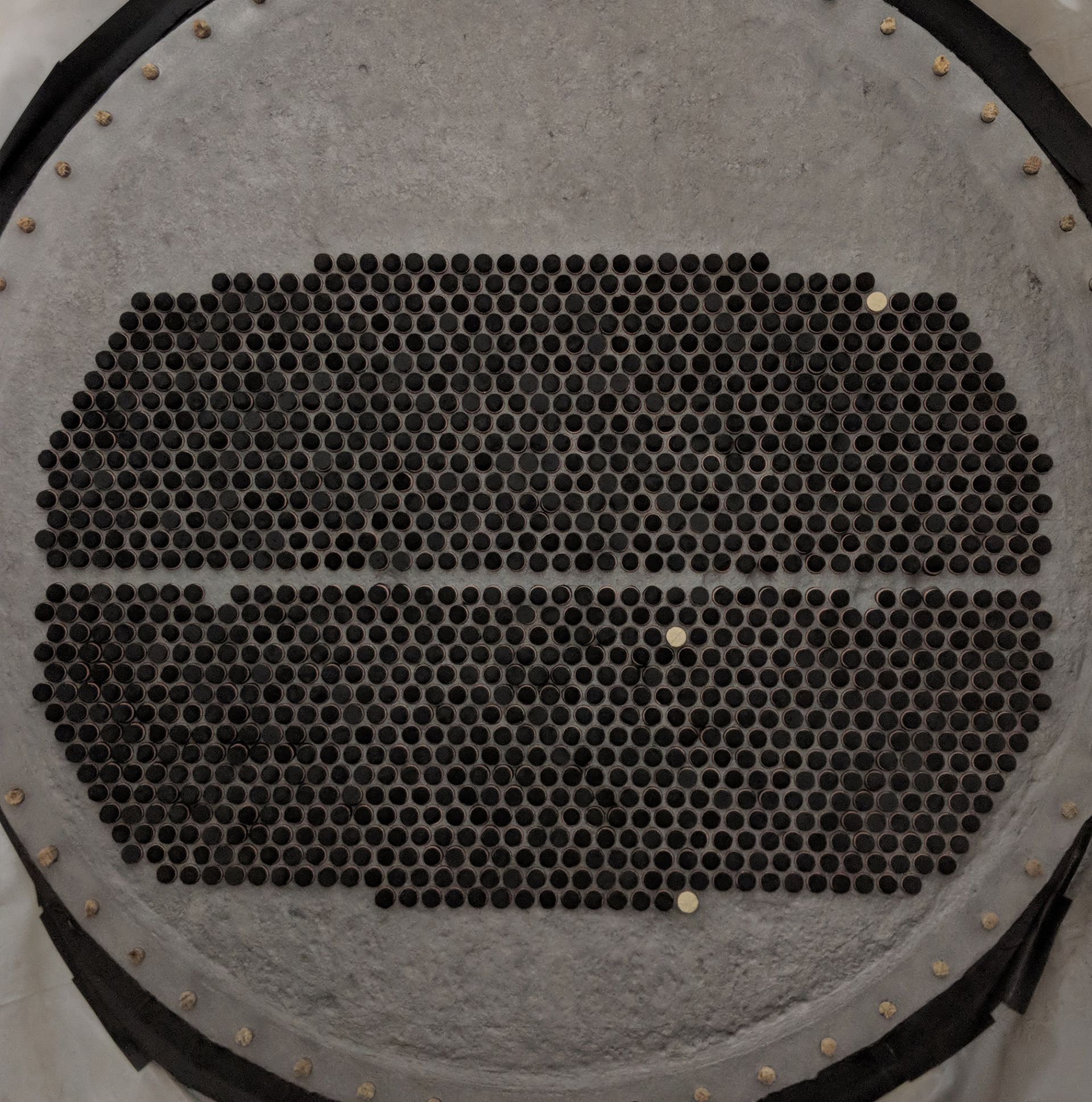

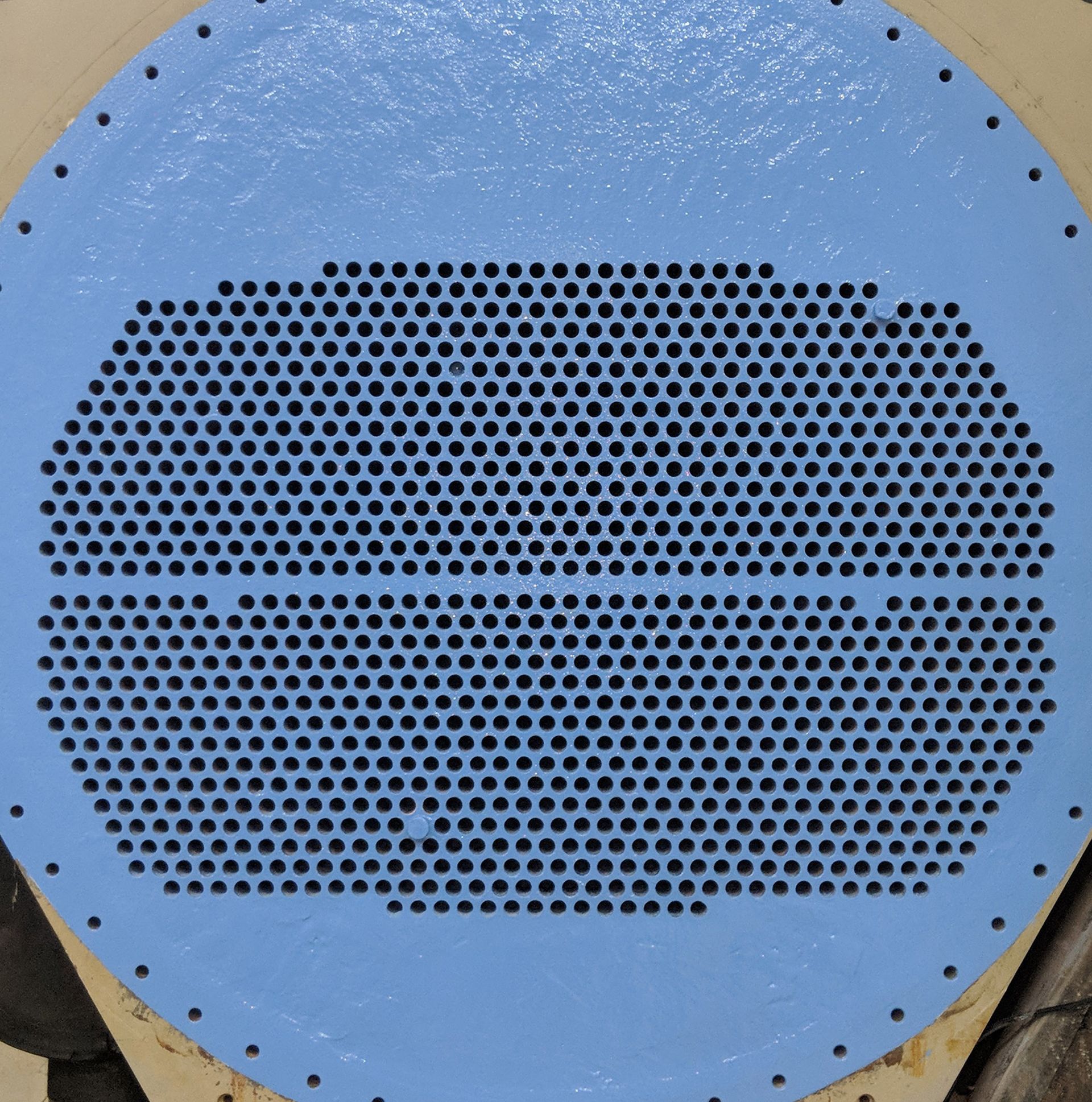

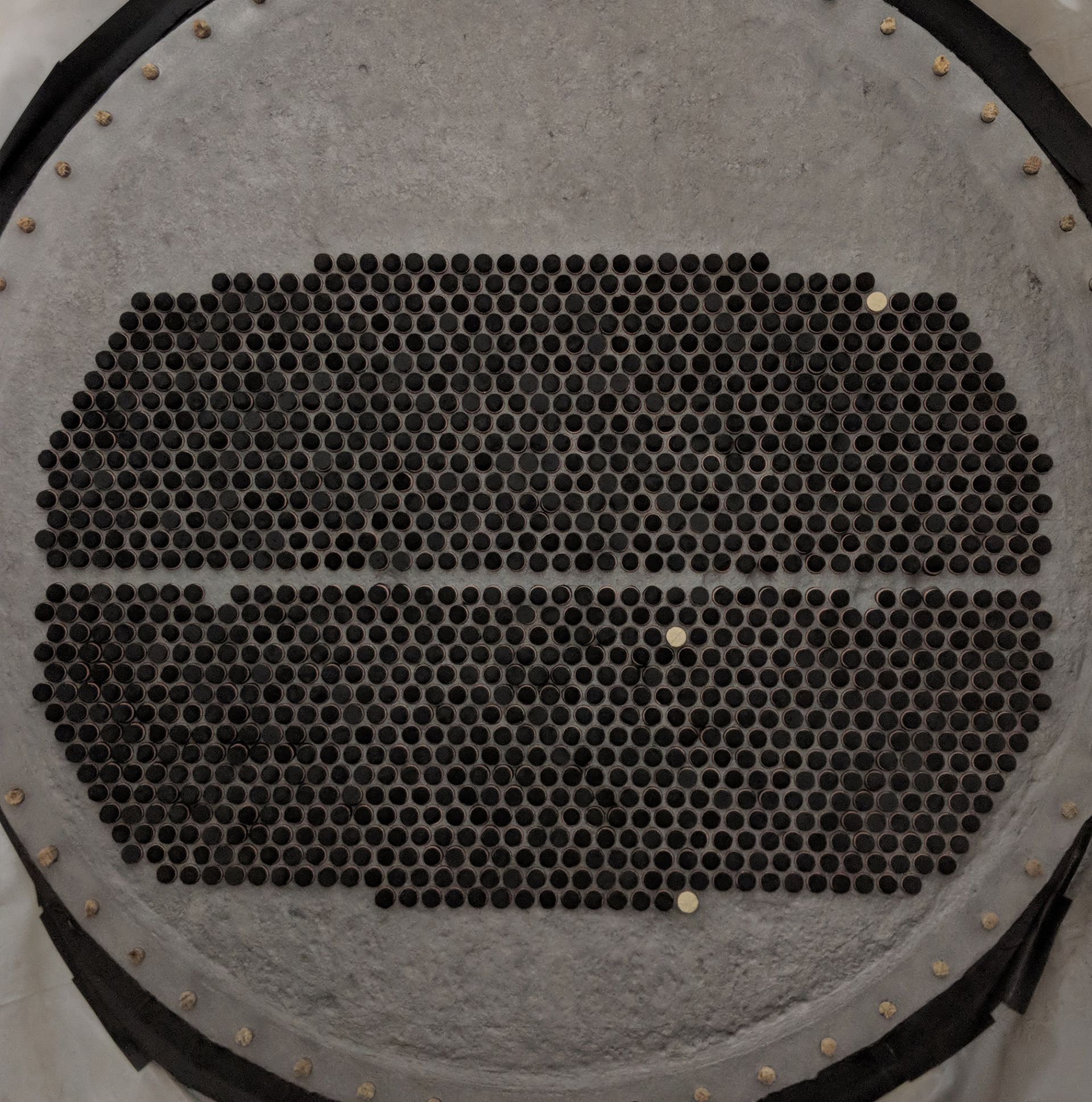

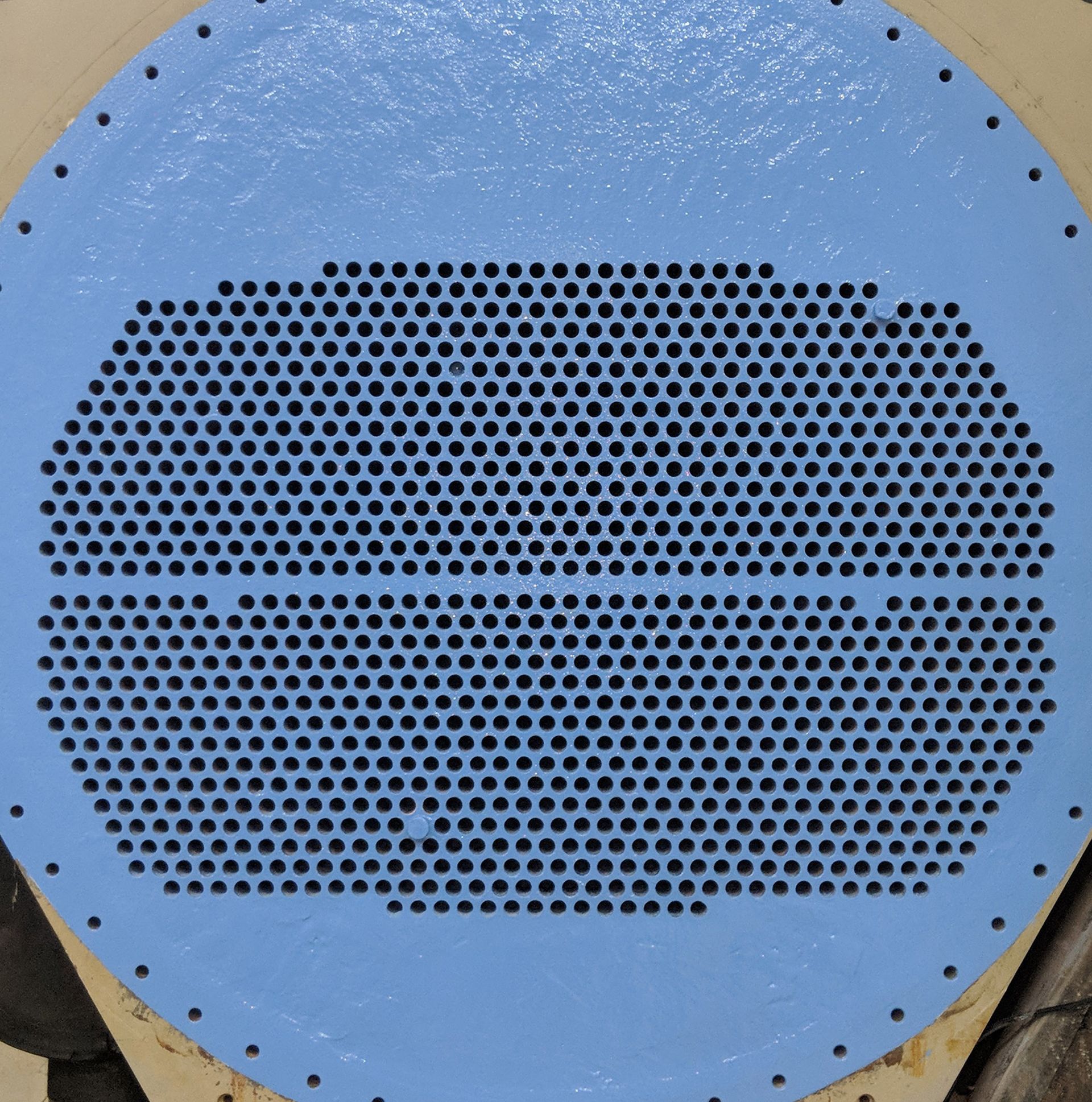

Tube Sheets

Advanced Specialty Coatings is the trusted name when it comes to repairing, restoring and protectively coating HVAC Chiller Heat Exchanger and Condenser Tube Sheets.

Our team of experts utilize cutting-edge techniques and high-quality materials to ensure your equipment is restored to optimal performance.

We are skilled at repairing your heat exchangers’ components such as tube sheets, flange faces, water boxes and end covers using cold applied metal repair composites and epoxy coatings rebuilding these components to their original profile.

This repair will:

- Provide long-term erosion and corrosion resistance

- Eliminate galvanic corrosion

- Prevent crevice corrosion

- Minimize equipment downtime

- Provide high temperature resistance

- Offer outstanding chemical resistance against a wide range of chemicals

- Eliminate the need for hot work

- Reduce expensive replacement costs

- Extend equipment life

Contact us to learn more about Tube Sheet Repair options. We're here to help.

Our expert team is accomplished at restoring the corrosive effects of chemical attacks, deterioration, and settlement cracking to Secondary Containment Systems.

We repair or replace the damage to your damaged concrete substrate and apply epoxy protective coatings to mitigate and prevent corrosion.

Advanced Specialty Coatings always implements strict control measures to minimize harm caused by spills, prevent environmental pollution, and ensure discharge is contained within the specified containment area.

Benefits of repairing, restoring, and protecting your containment structure:

- Safeguard your containment asset

- Extends the service life of secondary containment, pits, sumps, pits, channels, and bases

- Decreases maintenance costs

- Protects concrete, tile, and metal from damaging chemical attacks & corrosion

- Protects the environment from chemical spills, leaks, and contamination

You can trust Advanced Specialty Coatings to deliver high-quality results and maintain the integrity of your containment systems.

Contact us to learn more about Secondary Containment Repair options. We're here to help.

Cooling Towers

Cooling Towers are susceptible to damage from air, water, chemicals, and heat that can generate a severely corrosive environment. Advance Specialty Coatings offers an unparalleled range of specialty coating solutions to repair corrosive damage that protects and extends the life of damaged cooling towers.

Four common cooling tower repairs:

- Internal corrosion and chemical attack causes failure to joints and seams leading to dangerous and costly leaks. We use coatings, designed to withstand the highly corrosive environment inside cooling towers, creating a durable barrier against the array of chemicals, moisture, and heat present. At Advanced Specialty Coatings we are experts at restoring damaged metalwork, such as diffuser trays and holding pans using cold application of composite materials.

- Erosion by impingement impacts leading edges of fan blades that are frequently damaged from moisture and dust particles, causing severe erosion and corrosion. Using epoxy solutions we repair, rebuild, and coat eroded impinged fan blades to provide long-term erosion and corrosion protection, even on the most exposed leading edge.

- Mechanical damage caused by worn and damaged shafts. Using metal repair and rebuilding compounds, we can fix the damage in situ, limiting downtime and inefficiency. With the assistance of formers, cold-applied materials we restore scored shafts to their original dimensions, eliminating the need for replacement.

- Cooling Tower Pipeline Systems connect cooling towers to other HVAC components and are prone to external and internal corrosion and leaking issues. Our knowledge and expertise working with flexible repair materials and waterproof membranes allow us to deliver a durable solution to restore damage to joints and seams that can also be used in emergency situations.

Advanced Specialty Coatings ensures a swift return to service and that your tower will benefit from the most efficient, durable, long-lasting coating system available in the industry.

Contact us to learn more about Cooling Tower Repair Solutions. We're here to help.

Pipe Repair & Protective Coatings

Advanced Specialty Coatings specializes in epoxy and coating solutions to repair and protect a range of Damaged Pipe Problems in every industry and facility.

Pipes, values, and fittings often face damage and deterioration from corrosion, erosion, chemical attack, impact, and frost. Our repair solutions and expertise with engineered epoxy wrapping and coatings provide exceptional protection against these issues.

We fix pipe damage using cold-curing composite repair materials that strength weakened and corroded, holed, or leaking pipes and tank walls, often back to factory specifications.

At Advanced Specialty Coatings we are skilled at stopping the leak and sealing the area instantly, without the need to shut down the process.

Key Benefits:

- Rapid back to service time; In-situ or on-line pipe leak repair, sealing, restoring, and protecting with no need to shut down operation during the repair

- Minimize maintenance costs

- Provide long-term corrosion and erosion protection restoring the strength of holed, weakened and corroded pipe and tank walls life for many years

Contact us to learn more about how we can help Restore and Protect your Pipes. We're here to help.

Cooling Towers

Cooling Towers are susceptible to damage from air, water, chemicals, and heat that can generate a severely corrosive environment. Advance Specialty Coatings offers an unparalleled range of specialty coating solutions to repair corrosive damage that protects and extends the life of damaged cooling towers.

Four common cooling tower repairs:

- Internal corrosion and chemical attack causes failure to joints and seams leading to dangerous and costly leaks. We use coatings, designed to withstand the highly corrosive environment inside cooling towers, creating a durable barrier against the array of chemicals, moisture, and heat present. At Advanced Specialty Coatings we are experts at restoring damaged metalwork, such as diffuser trays and holding pans using cold application of composite materials.

- Erosion by impingement impacts leading edges of fan blades that are frequently damaged from moisture and dust particles, causing severe erosion and corrosion. Using epoxy solutions we repair, rebuild, and coat eroded impinged fan blades to provide long-term erosion and corrosion protection, even on the most exposed leading edge.

- Mechanical damage caused by worn and damaged shafts. Using metal repair and rebuilding compounds, we can fix the damage in situ, limiting downtime and inefficiency. With the assistance of formers, cold-applied materials we restore scored shafts to their original dimensions, eliminating the need for replacement.

- Cooling Tower Pipeline Systems connect cooling towers to other HVAC components and are prone to external and internal corrosion and leaking issues. Our knowledge and expertise working with flexible repair materials and waterproof membranes allow us to deliver a durable solution to restore damage to joints and seams that can also be used in emergency situations.

Advanced Specialty Coatings ensures a swift return to service and that your tower will benefit from the most efficient, durable, long-lasting coating system available in the industry.

Contact us to learn more about Cooling Tower Repair Solutions. We're here to help.

Pipe Repair & Protective Coatings

Advanced Specialty Coatings specializes in epoxy and coating solutions to repair and protect a range of Damaged Pipe Problems in every industry and facility.

Pipes, values, and fittings often face damage and deterioration from corrosion, erosion, chemical attack, impact, and frost. Our repair solutions and expertise with engineered epoxy wrapping and coatings provide exceptional protection against these issues.

We fix pipe damage using cold-curing composite repair materials that strength weakened and corroded, holed, or leaking pipes and tank walls, often back to factory specifications.

At Advanced Specialty Coatings we are skilled at stopping the leak and sealing the area instantly, without the need to shut down the process.

Key Benefits:

- Rapid back to service time; In-situ or on-line pipe leak repair, sealing, restoring, and protecting with no need to shut down operation during the repair

- Minimize maintenance costs

- Provide long-term corrosion and erosion protection restoring the strength of holed, weakened and corroded pipe and tank walls life for many years

Contact us to learn more about how we can help Restore and Protect your Pipes. We're here to help.

Our Services

Tube Sheets

Advanced Specialty Coatings is the trusted name when it comes to repairing, restoring and protectively coating HVAC Chiller Heat Exchanger and Condenser Tube Sheets.

Our team of experts utilize cutting-edge techniques and high-quality materials to ensure your equipment is restored to optimal performance.

We are skilled at repairing your heat exchangers’ components such as tube sheets, flange faces, water boxes and end covers using cold applied metal repair composites and epoxy coatings rebuilding these components to their original profile.

This repair will:

- Provide long-term erosion and corrosion resistance

- Eliminate galvanic corrosion

- Prevent crevice corrosion

- Minimize equipment downtime

- Provide high temperature resistance

- Offer outstanding chemical resistance against a wide range of chemicals

- Eliminate the need for hot work

- Reduce expensive replacement costs

- Extend equipment life

Contact us to learn more about Tube Sheet Repair options. We're here to help.

Our expert team is accomplished at restoring the corrosive effects of chemical attacks, deterioration, and settlement cracking to Secondary Containment Systems.

We repair or replace the damage to your damaged concrete substrate and apply epoxy protective coatings to mitigate and prevent corrosion.

Advanced Specialty Coatings always implements strict control measures to minimize harm caused by spills, prevent environmental pollution, and ensure discharge is contained within the specified containment area.

Benefits of repairing, restoring, and protecting your containment structure:

- Safeguard your containment asset

- Extends the service life of secondary containment, pits, sumps, pits, channels, and bases

- Decreases maintenance costs

- Protects concrete, tile, and metal from damaging chemical attacks & corrosion

- Protects the environment from chemical spills, leaks, and contamination

You can trust Advanced Specialty Coatings to deliver high-quality results and maintain the integrity of your containment systems.

Contact us to learn more about Secondary Containment Repair options. We're here to help.

Pipe Repair & Protective Coatings

Advanced Specialty Coatings specializes in epoxy and coating solutions to repair and protect a range of Damaged Pipe Problems in every industry and facility.

Pipes, values, and fittings often face damage and deterioration from corrosion, erosion, chemical attack, impact, and frost. Our repair solutions and expertise with engineered epoxy wrapping and coatings provide exceptional protection against these issues.

We fix pipe damage using cold-curing composite repair materials that strength weakened and corroded, holed, or leaking pipes and tank walls, often back to factory specifications.

At Advanced Specialty Coatings we are skilled at stopping the leak and sealing the area instantly, without the need to shut down the process.

Key Benefits:

- Rapid back to service time; In-situ or on-line pipe leak repair, sealing, restoring, and protecting with no need to shut down operation during the repair

- Minimize maintenance costs

- Provide long-term corrosion and erosion protection restoring the strength of holed, weakened and corroded pipe and tank walls life for many years

Contact us to learn more about how we can help Restore and Protect your Pipes. We're here to help.

Tell Us About Your Repair Project

© 2025 Advanced Specialty Coatings, LLC